- #CUTLIST OPTIMIZER FOR PC HOW TO#

- #CUTLIST OPTIMIZER FOR PC FULL#

- #CUTLIST OPTIMIZER FOR PC SOFTWARE#

- #CUTLIST OPTIMIZER FOR PC FREE#

This is a pretty old thread, but thought I'd add a more recent experience. Reason: Rephasing for better understanding Last edited by Osvaldo Cristo 02-17-2019 at 2:20 PM.

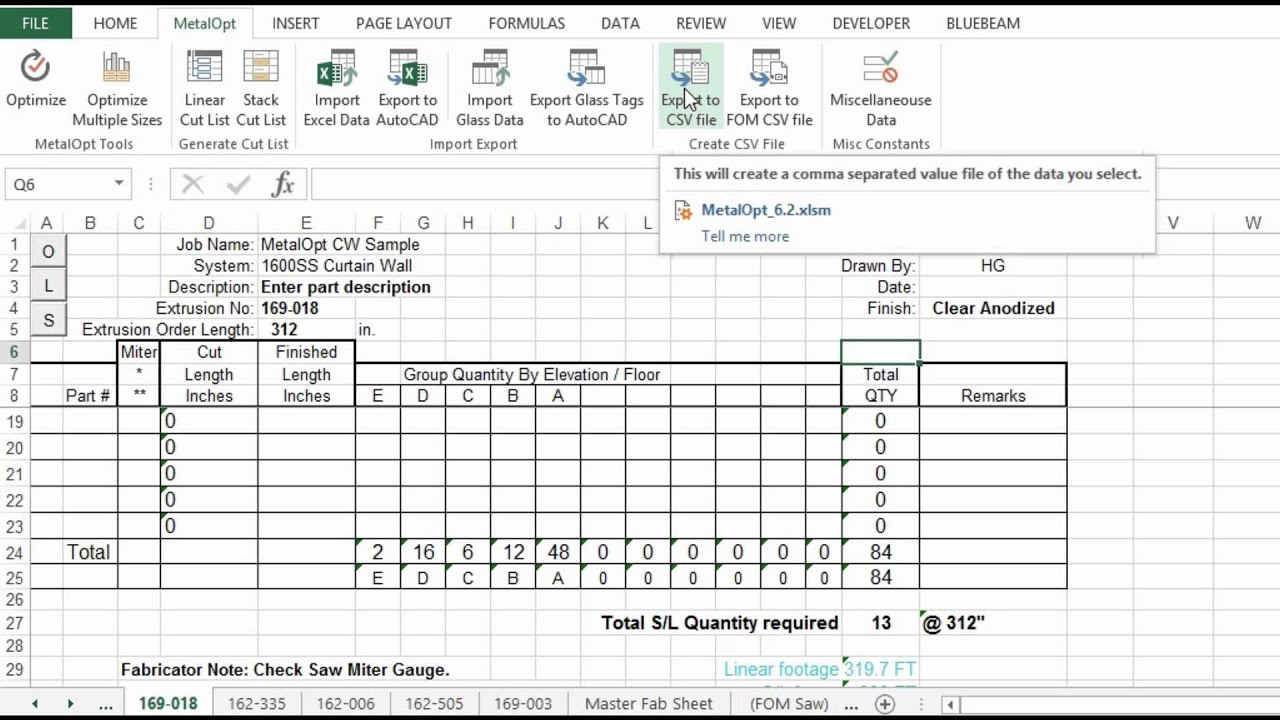

#CUTLIST OPTIMIZER FOR PC SOFTWARE#

I do not miss any software to make that.īottom line is that kind of software optimization apps can be an overkill to some people. Since then I prefer to use my drawing skills to optimize panels and board cuts. but I discovered that for my use it wasn't an exactly great idea: except for a couple of years in the 1990s I always had less than five panels (or boards) to optimize a year, so to make that manually looked me better and a fast solution. Of course I had then no graphic output but the text output was good enough. first using FORTRAN IV and afterwards C language including the "sophistication" to define saw kerf and the grain direction for each piece. I think I wrote that previously at those fora - I wrote a program to optimize my cut list on the very beginning of the 1980s. Here's an example of how I arranged my panel vs how the tool did. It shows all dimensions, allows you to include saw kerf, and also lets you label everything. It doesn't always arrange them the way I would cut them from the plywood given I might want my waste pieces optimized in a different size, but for those of you who don't use CAD or other cut list optimizing software, this seems to be a pretty cool tool. I did a quick google search and found this: This got me thinking there must be some tools out there on the web for optimizing panel usage. When cutting panels out of a sheet of plywood or other sheet goods I have always drawn everything up in AutoCAD and arranged things for optimizing the panel usage.

It sure does help your workflow and visualization. Thats when peoples heads spin because they are use to large waste drops due to cutting on a table saw.

#CUTLIST OPTIMIZER FOR PC FULL#

Wait til you start optimizing for CNC when your logic is full lenght X/Y axis rips only and your no longer constrained by that method and parts can be tucked in small notches and waste areas. At that point the answer is that the software has it correct lol. Ive sat with guys who want to make you turn this part and try to fit that part over there and wont that fit in that little waste piece and after two or three iterations I tell them we are going to lawyer style billing and every minute of shifting parts is $5. But no matter how often I take the time for the heck of it to re-orient the parts in the manner "they would have cut the sheet" and show them that they would have spread into an extra sheet or two, they dont get it. They would twist a part around or say oh that one part the grain orientation doesnt matter so Id have rotated, and so on. I go through this regularly cutting parts for others. A big part is coming to the realization that giving things over to the software will usually mean seeing a bunch of things where you think your smarter than the software and the software is wrong, but when you look at your balance sheet at the end of a project you'll see that your waste material in the dumpster is less.

It lays them out as best it can calculate mathematically based on yeild and has no ability to allow for the fact that you may like or want your drops from job "A" on the Y axis of the sheet but on this job B-2.0 you want them on the X axis.

#CUTLIST OPTIMIZER FOR PC FREE#

Our cut sheet calculator use these powerful methods so the final solution is really close to optimal solution or is optimal solution.įor hobbyists, tradesmen, small companies or for every personal or commercial entity, who do not require to solve complex sheet cutting optimization problems (when our Free plan is sufficient), we provides our cut optimizer completely FREE OF CHARGE.No cutlist optimization tool will lay things out "the way you would" (they lay them out better than that lol). Heuristics and evolutionary algorithms are much better choice for complex problems. Because cutting stock problem is a subclass of NP-hard problems, it is very time consuming to find optimal solution for complex tasks but also for fairly simple tasks.

This cut list calculator will help you with this issue in real time with couple of clicks.

#CUTLIST OPTIMIZER FOR PC HOW TO#

In industry, 2D cutting stock problem is one of the most important tasks how to cut sheet material with maximal material yield and minimal waste. This online cut list optimizer is kind of cutting optimization software specialized for cutting rectangular material like wood, glass or sheet metal.

0 kommentar(er)

0 kommentar(er)